DTG Printer

Revolutionise Your Apparel Business with Direct-to-Garment (DTG) Printing!

✅ True CMYK Colour Reproduction – Achieve stunning, complex designs with no screen setup

✅ Eco-Friendly Water-Based Inks – Odourless, non-toxic, and safe for all ages

✅ Small Batch Friendly – Print 1 piece or 1000s with equal ease and quality

🔥 Limited-Time Offer! Get 15% off your first DTG printer + free training.

Submit Inquiry Now!

Everpro Print is a professional one of the best DTG printer manufacturers and wholesale suppliers from China.

As a leading industrial DTG printer manufacturer, we specialise in high-performance direct-to-garment printing solutions for global distributors, print shops, and OEM partners. Our factory-direct pricing delivers 45 %+ profit margins for resellers with the lowest MOQ of 1 unit.

Elevate your clothing line with Everpro’s advanced DTG printers—the ultimate solution for high-resolution, soft-handfeel prints on cotton, polyester, and blended fabrics. Perfect for custom t-shirts, sportswear, fashion brands, and promotional merchandise, our DTG technology delivers photorealistic designs with unmatched vibrancy and durability.

What is DTG Printing?

DTG (Direct-to-Garment) printing is a digital printing technology that directly applies images onto fabrics using high-precision inkjet technology. DTG printers transfer designs from a computer directly onto textile surfaces, commonly used for printing on T-shirts, hats, hoodies, pants, shoes, and various other fabrics. Compared to traditional screen printing or heat transfer methods, DTG printing achieves finer details and richer colour gradients, making it ideal for small-batch and customised production needs.

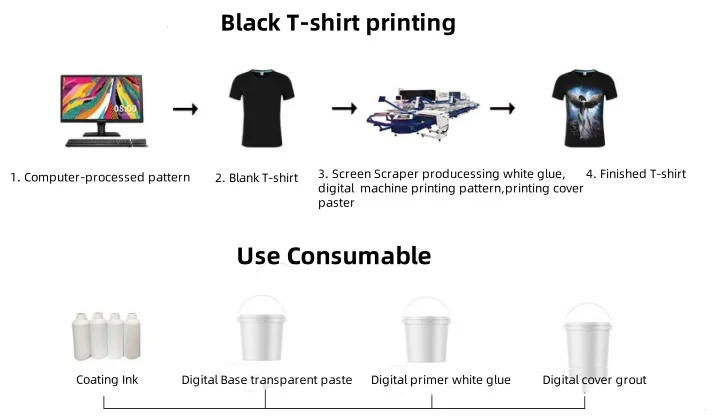

DTG Printer Workflow

Design Creation: Users create designs using graphic design software (e.g., Adobe Photoshop, Illustrator), ensuring the resolution and color mode are suitable for printing.

Print Preparation: Transfer the design file to the DTG printer’s control system. The printer prepares the fabric, often including pre-treatment to enhance ink adhesion.

Direct Printing: The inkjet head precisely sprays ink onto the fabric, directly printing the design onto the garment layer by layer.

Drying and Curing: After printing, the fabric is dried to ensure the ink sets completely, enhancing durability and color vibrancy.

Post-Processing: Additional steps like washing or shaping may be performed to ensure long-lasting print quality and garment comfort.

Applications of DTG Printing

DTG printing is widely used in the following fields:

Apparel Industry: Custom printing on T-shirts, sportswear, hoodies, etc.

Home Decor: Printing on pillows, bed sheets, curtains, and other fabric products.

Gift Customization: Personalized backpacks, hats, and other items.

Brand Promotion: Unique promotional apparel or giveaways for business.

Here you can find the Best DTG Printers for Custom Apparel and Small Businesses and DTG Printer for Medium Business and Large-Scale Industrial Production

Advantages Of DTG Printing

High Precision: Capable of intricate designs and fine details.

Rich Colors: Wide color range with smooth gradients and shading.

Ideal for Small Batches: No need for complex printing molds, perfect for customized, small-scale production.

Eco-Friendly: Uses water-based inks, free of harmful substances.

Breathable: Minimal impact on fabric breathability.

DTF VS DTG |

||

| Comparison Item | DTF Printing | DTG Printing |

| Working Principle | Prints the design on a PET film, then transfers it to the garment using heat. | Directly prints ink onto the garment. |

| Suitable Materials | Works on various materials, including cotton, polyester, blends, leather, wood. | Primarily suitable for cotton garments; dark fabrics require pretreatment. |

| Color Performance | Vibrant colors, ideal for complex patterns and gradients. | Good color performance, but dark fabrics require white underbase pretreatment. |

| Printing Speed | Faster, suitable for small to medium batch orders. | Slower, suitable for small batches or single-piece customization. |

| Durability | High durability, withstands multiple washes. | Good durability, but may fade after prolonged washing. |

| Dark Fabric Printing | No pretreatment needed, can print directly on dark fabrics. | Requires white underbase pretreatment, increasing cost and time. |

| Light Fabric Printing | Excellent results with vibrant colors. | Excellent results with vibrant colors. |

| Environmental Impact | Uses hot-melt powder, which may generate dust pollution. | Uses water-based ink, relatively eco-friendly. |

| Ease of Operation | Simple to operate, suitable for beginners. | Complex operation, requires technical expertise. |

| Equipment Size | Compact equipment, suitable for small workspaces. | Larger equipment, requires more space. |

| Application Scenarios | Custom apparel, promotional products, home decor, personalized gifts, etc. | Custom apparel, art creation, small-scale production, etc. |

| Pattern Precision | High precision, suitable for intricate designs. | High precision, but dark fabrics may affect results. |

How to Choose the Right DTG Printer?

Determine Needs: Choose a model based on production scale (small or large batches) and materials.

Print Quality: Ensure the printer supports high resolution for detailed, vibrant prints.

Material Compatibility: Verify the printer supports various fabrics and materials.

Ink System: Opt for eco-friendly, water-based inks for safety and color performance.

After-Sales Service: Reliable technical support and service are crucial for long-term operation.

FAQ (Frequently Asked Questions)

Does DTG ink affect clothing?

DTG uses water-based inks designed for textiles. After curing, the prints are durable and safe for skin and the environment.

What materials can DTG printing be used on?

DTG printers can print on cotton, polyester, blends, and various other fabrics.

Is DTG printing suitable for mass production?

Yes, we offer machines for small-scale production as well as large-scale industrial DTG printers.