DTF-S05 DTF Transfer Film

DTF-S05 DTF Transfer Film Main Packing Parameters:

Size: 60cm x 100m/ volume

Packing size: 65*34*19cm/ box (2 rolls)

Weight: 15 kg/box (2 rolls)

Category: Single side/Double side

JL Single mask thickness: 78um

JL Double mask thickness: 80um

AB single mask thickness: 83um

ABDouble mask thickness: 88um

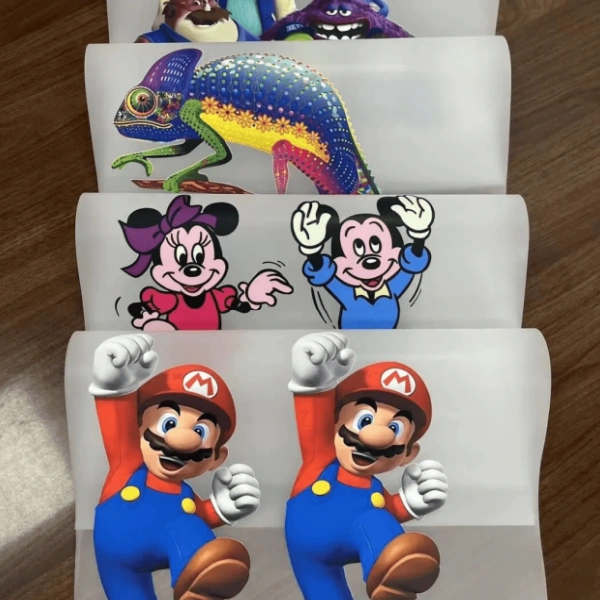

Product Description

First, What is DTF Transfer Film?

DTF Transfer Film (Direct-to-Film Transfer Film) is a multilayer special film designed for the digital direct printing process. The core technology is to print the pattern directly on PET film and then transfer the pattern to the target material (e.g. textile, plastic, metal, etc.) by hot pressing.

- Process flow: pattern design → film printing → shaking powder curing → thermal transfer to target → cooling molding.

- Multi-layer structure: usually consists of base layer, release layer, adhesive layer, printing layer, protective layer and anti-static layer to ensure transfer effect and durability.

Second, Main features:

- Surface Treatment:

- Single-sided: Back coated with a glossy finish.

- Double-sided: Back coated with a matte finish.

- Printing Performance:

- Vibrant colors deliver outstanding visual effects.

- Clean powder shaking, ensuring clear patterns without impurities.

- Instant peeling with no pressure, making operation simple and fast.

- Versatility:

- Suitable for various materials, with no fabric limitations.

- Compatible with both cold and hot peeling, adapting to different working environments.

- High ink absorption, ensuring rich and long-lasting colors.

- Ink Compatibility:

- Wide ink compatibility, supporting multiple ink types.

- Operational Performance:

- Anti-stick and anti-static features ensure smooth operation without misalignment.

Third, Core Features and Benefits:

Third, Core Features and Benefits:

- Excellent printing effect

- Bright colors, high color retention, support for high-precision complex patterns (resolution up to 1200 dpi).

- After transferring the soft feel of the pattern, color saturation is close to screen printing and 30%-50% softer than the traditional film.

2. Wide material adaptability

- Textile: Compatible with cotton, polyester, nylon, blended fabrics and leather.

- Non-textile: can be transferred to glass, metal, ceramics, cell phone cases, game consoles and other shaped materials.

3. Efficient and flexible

- Small batch friendly: no need for plate making, support single piece printing, suitable for personalization.

- Fast production speed: integrated printing, powder shaking and baking functions to shorten the delivery cycle.

4. Environmental Advantages

- Water-based ink: low VOC (Volatile Organic Compounds) emissions, in line with EU environmental standards.

- Low waste film rate: digital cutting reduces material waste, and waste film can be recycled and disposed of.

5. Strong durability - Patterns are cured by hot pressing, are resistant to washing, abrasion and cracking, and can withstand more than 50 times of machine washes.

Fourth, the typical Application Scene of the DTF transfer film

- Clothing industry: T-shirts, sweatshirts, sportswear, hats, canvas shoes and other personalized printing.

- Electronic products: cell phone cases, headset cases, gamepads, keyboard keycaps 3D pattern transfer.

- Industrial products: ceramic cups, metal tags, plastic toys, car interior parts of the pattern transfer.

- Advertising & Decoration: On-demand production of exhibition banners, interior decorative paintings, and promotional gifts (e.g. mugs, pillows).

Fifth, the cooperated DTF Printers of the DTF transfer film:

Click Here For more details on the DTF Printers. More Details

FAQ

What's the difference between DTF Transfer Film and regular heat transfer film?

- DTF film is designed specifically for water-based inkjet printing and doesn’t require pre-coating to hold ink.

- Regular heat transfer films typically need solvent-based inks or additional coatings and are not compatible with DTF hot melt powder processes.

What materials is DTF Transfer Film compatible with?

Works on fabrics like cotton, polyester, blends, denim, and canvas, and can also transfer to wood, ceramic, and metal (with adjusted temperature and pressure).

What should I consider when storing DTF Transfer Film?

- Store in a cool, dry place, away from direct sunlight.

- Avoid moisture and high temperatures, as they may cause film warping or release layer failure.

Why does the design peel off after transfer?

Possible reasons:

- Insufficient temperature/pressure → Adjust heat press settings.

- Uneven hot melt powder → Ensure full and even powder coverage.

- Incompatible fabric → Test different materials or apply a pre-treatment (e.g., primer).