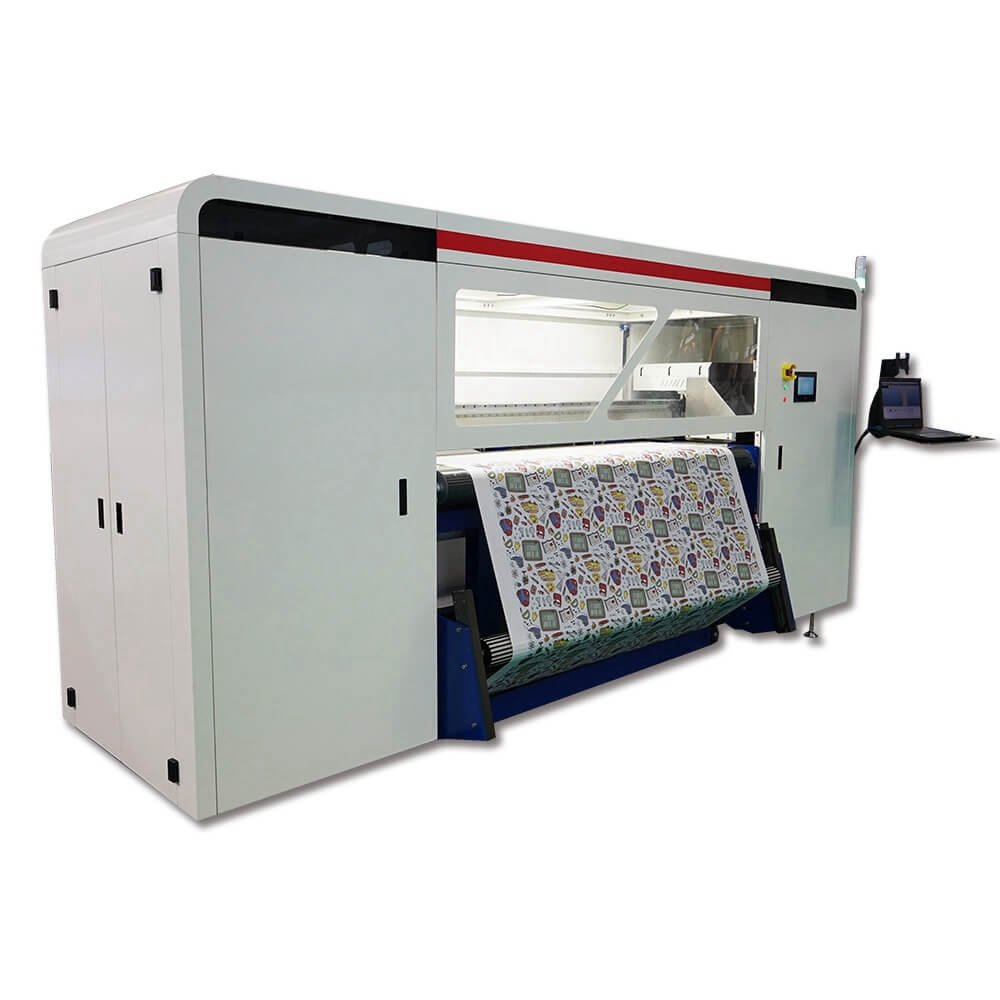

EP-P01 Digital Large Format Sublimation Printer

Digital Large Format Sublimation Printer:

Maximum roll diameter for paper winding and unwinding:

Paper Unwind:10000m Paper wind:3500m

Technical Data

Additional information

| Print Head | 15/16*Epson I3200 |

|---|---|

| Print Width | Max 1900mm |

| Printing Speed | 15 nozzle production mode: 240*1800 dpi/1pass-540㎡/H 16 nozzle production mode: 360*1200 dpi/1pass-620㎡/H |

| RIP Software | Motel 6.1 Pro |

Product Description

Everpro Print – China’s Premier Large-Format Sublimation Printer Manufacturer & Global Supplier

Industrial-Scale Transfer Printing Solutions

✔ Extra-Wide Production | 1.6m–3.2m printing width options

✔ Vibrant Color Output | 8-channel high-density ink system

✔ Rapid Drying Technology | 50% faster heat transfer than competitors

Manufacturing Advantages

✓ Unbeatable Pricing | 40–60% below European/American brands

✓ Tailored Configurations | Custom sizes/heat press integration

✓ No Minimum Orders | Single-machine purchases welcome

Complete Production Support

• Turnkey Installation | Remote calibration + optional on-site training

• Authentic Consumables | Sublimation inks/paper/parts kits

• Dedicated Technical Team | Multilingual specialists on call

Digital Large Format Sublimation Printer

Digital Large Format Sublimation Printer Data:

| Device Type | Large Format Sublimation Printer | Printhead Head | Epson-I3200-A1 |

| Print Head Quantity | 15、16 | Working Environment | Temperature:20C-28C Humidity:45-70% |

| Image Format | JPG/TIF/PDF | Working Power Supply | 380V 50Hz/60Hz |

| Suitable Paper | ≥31g | Outside Dimensions | 3950*1260*1900mm |

| RiP Software | Montel 6.1 | Reel Size | 2500*1050*1050mm |

| Print Speed | 240*1800dpi 540㎡/h 360*1200dpi 620㎡/h | Weight | 1380kgs |

| Alarm System |

1. Lack of ink alam 2.Sprey car collision prevention |

Power | 4000w |

| Max Print Width | 1900MM | Optional Configuration | |

| Device Features |

|

||

Digital Large Format Sublimation Printer Parts Details:

|  |  |

| Nozzle collision avoidance: Anti-collision spary car extendsthe service life of sprinkler head | All aluminum ink stack:15 all aluminum in kstack automatic cleaningand moisturizing | Ink monitoring: Large capacity ink barrel,long print life, inkshortage alarm device Avoidprinting ink loss |

|  |  |

| Stable: Magnetic levitation imported silentrail printing precision | Suction platform: The arc-shaped air suctionplatform is more smooth | Closed system: Upgrade thestructure of large rubber rollerto ensure a more stable paperwalking.Stepprecise effect is better |

Textile Fabric Transfer Inkjet Printer Application:

Sublimation printing, known for its vibrant colors, durability, and wide range of applications, is extensively used across various industries. Examples include sportswear such as soccer jerseys print, basketball uniforms printing, cycling outfits printing, and swimwear printing; home textile products printing like bed sheets printing, pillow printing, curtains printing, and tablecloths printing; decorative fabrics for sofa covers printing and cushions printing; advertising flags and banners printing for outdoor promotions and exhibitions; promotional gifts such as custom pillows printing, aprons printing, and mouse pads printing; shoe printing for designing patterns on sneakers and casual shoes; and hat printing for baseball caps printing and bucket hats printing. It not only meets the needs of both personalized customization and mass production but also provides efficient and high-quality printing solutions for various industries.

Textile Fabric Transfer Inkjet Printer Working Flow:

Digital Large Format Sublimation Printer Cooperated Machine:

Sublimation Printer FAQ

How can I get a quote for the machine?

You can visit our official website, select the product you’re interested in, and provide your email address, phone number, and product specifications. We will respond within 0-12 hours. Alternatively, you can message us on WhatsApp for immediate assistance.

What is the delivery time?

Typically, after receiving full payment or a deposit, we arrange shipment within 7-25 working days. Custom orders may require additional time.

What kind of technical support do you provide? How do you resolve issues during use?

(1) Pre-sales consultation: Our sales team offers tailored recommendations based on your needs to ensure the UV DTF printer aligns with your business goals.

(2) Training and tutorials: We provide detailed operation training and tutorials to help you maximize the machine’s capabilities and improve productivity.

(3) Fault resolution: If an issue arises, our technicians will analyze the problem based on your description, photos, or videos and provide a suitable solution promptly.

How can I place an order? What payment methods do you accept?

(1) After confirming the order details with our sales team, we will send you a proforma invoice. Once payment is received, we will arrange production and discuss shipping options (sea, air, or rail) based on your needs.

(2) Payment methods: T/T, Letter of Credit, PayPal, Western Union.