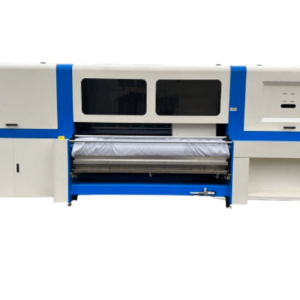

EP-I01A Belt-Guided Japan Kyocera Industrial Printhead Roll Textile Digital Fabric Printer

Roll Textile Digital Fabric Printer Top Feature:

- One-Key Shutdown.

- Fully Automatic Guide Belt Cleaning.

- Quick Access Buttons for Printhead/Wiper Maintenance.

- Ink-Free and Clog-Free Operation During Any Standstill, with Long-Term Downtime Capability.

- One-Key Mute for Alarm Status.

Technical Data

Additional information

| Print Width | Max 1810/2610mm |

|---|---|

| Ink | CMYK/ORGB |

| Weight | 400kgs/500kgs |

Product Description

Everpro Print – China’s Leading Roll-to-Roll Textile Digital Printer Manufacturer & Wholesale Supplier

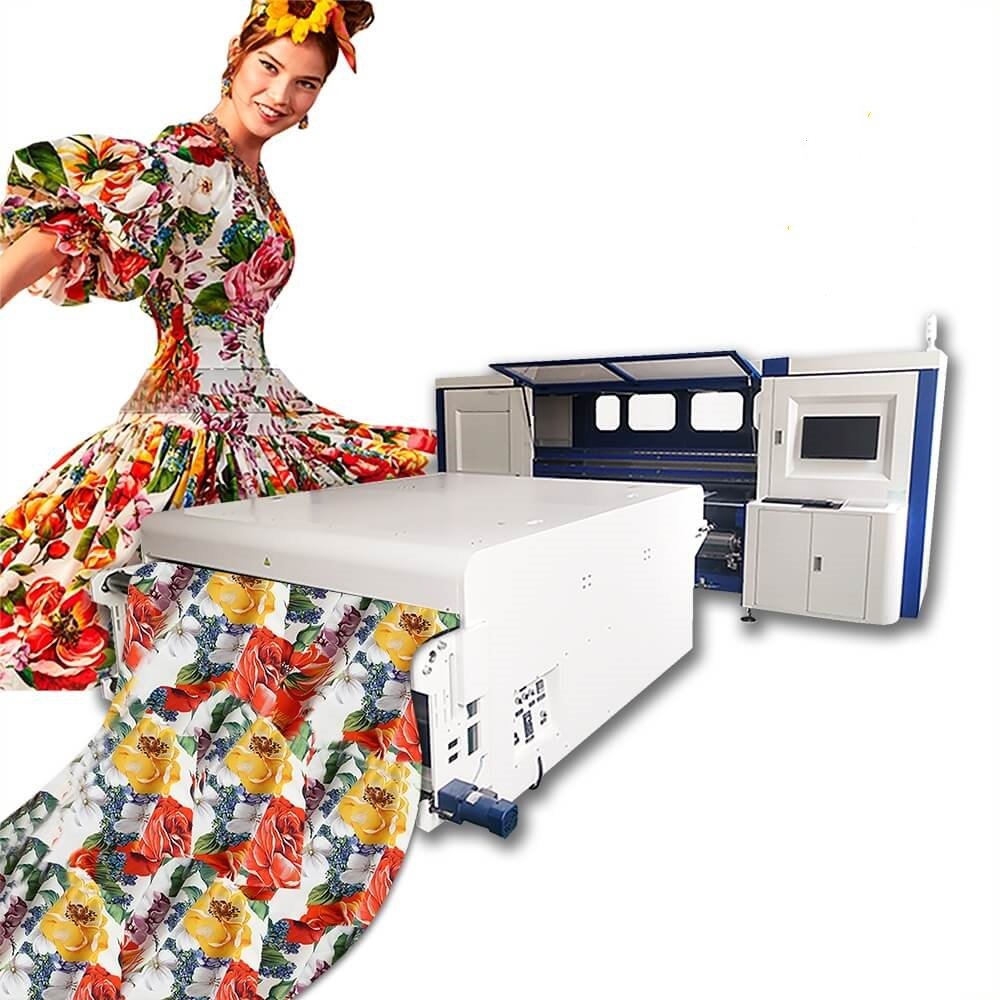

Industrial-Grade Fabric Printing Solutions

✔ Continuous Roll Printing – Supports 24/7 bulk production

✔ Vibrant Color Output – 8-color ink system with 98% Pantone matching

✔ Wide Material Compatibility – Cotton/polyester/silk/blends

Competitive Manufacturing Advantages

✓ Factory-Direct Pricing – 30%-80% below European/American brands

✓ Full Customization – Adjustable width/speed/ink configuration

✓ 1-Unit MOQ – Perfect for startups and sample development

Complete Production Package

• Professional Setup – Remote/onsite installation support

• Genuine Consumables – Textile inks, printheads, maintenance kits

• Dedicated Support – Multilingual technical consultants

EP-I01A Belt-Guided Japan Kyocera Industrial Printhead Roll Textile Digital Fabric Printer:

Belt-Guided Japan Kyocera Industrial Printhead Roll Textile Digital Fabric Printer Data:

| Device Type | EP-I01A Roll Textile Digital Fabrice Printer | Printhead | Japan Kyocera |

| Print Head Quantity | 8、12、16、32 | Working Environment | Temperature:20C-28C Humidity:45-65% |

| Ink | 4colors(CMYK) 8colors(CMYKORGB) | Working Power Supply | 380V 50Hz/60Hz |

| Suitable fabric | Cotton、linen、Silk polyester、nylon | Outside Dimensions | 4950*2650*2000mm 5760*2650*2000mm |

| RiP Software | Maintop/Neostampa | Water Supply Pressure | 0.6Mpa 1m³/H |

| Print Speed | 200-270㎡/h 350-550㎡/h | Weight | 4000kgs/5500kgs |

| Printhead Maintenance | Automatic Cleaning Automatic Moisturizing Automatic ink scraping | Power | 7.5kw/10kw |

| Max Print Width | 1810/2610mm | Optional Configuration | Ink capsule heating |

| Device Features |

|

||

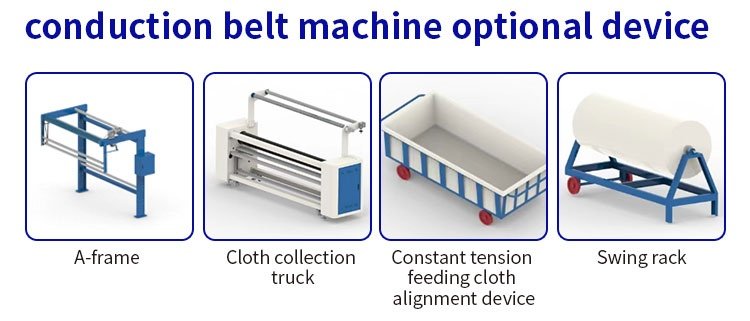

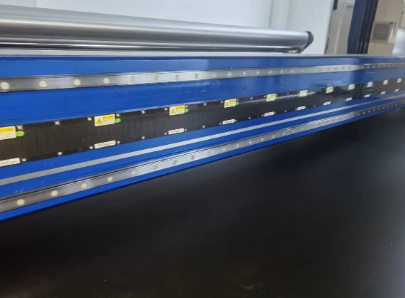

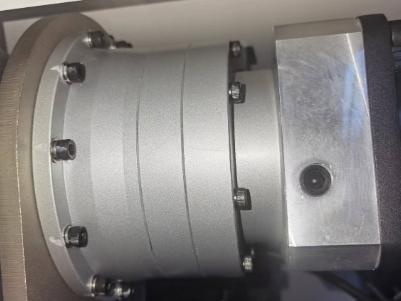

EP-I01A Belt-Guided Japan Kyocera Industrial Printhead Roll Textile Digital Fabric Printer Parts Details:

|  |  |

| Super quiet rail brand: THK Advantage: high precision silent | Advantages of linear motor maglev system: high precision, silent and maintenance-free | High precision reducer imported from Japan |

|  |  |

| Swiss imported high precision belt brand: Habasi | Servo motor drive brand: xinjie | Servo drive brand: Gaochuang |

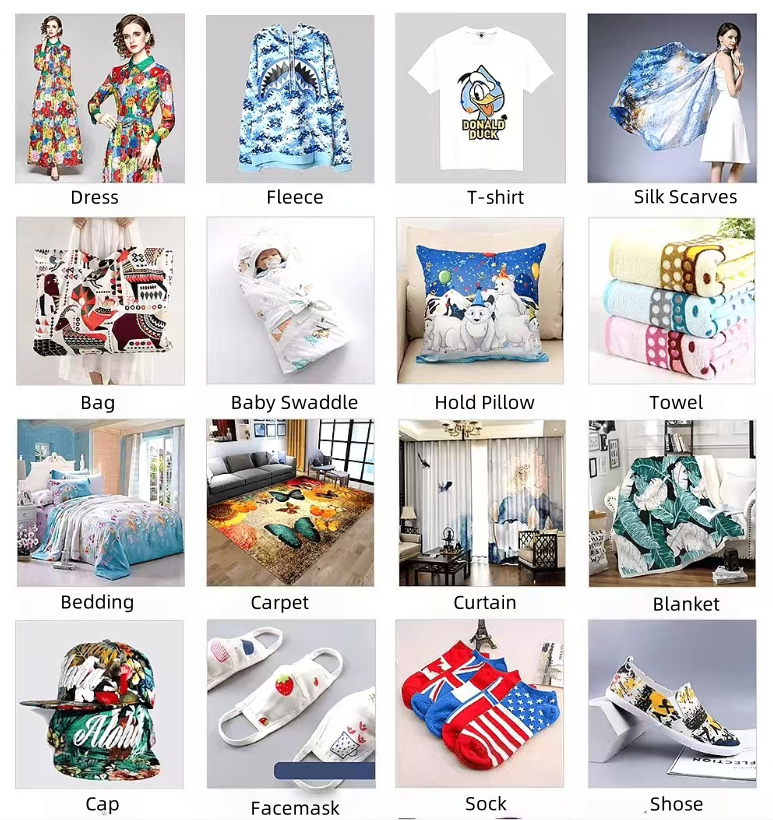

Roll Textile Digital Fabric Printer Application:

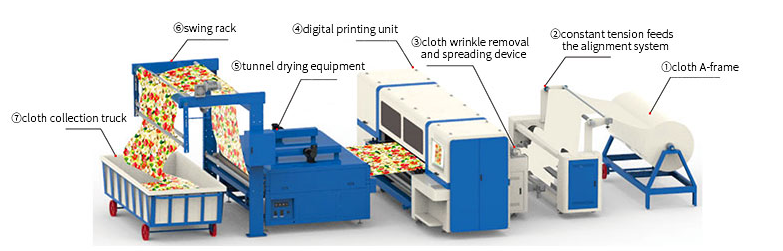

Roll Textile Digital Fabric Printer Working Flow:

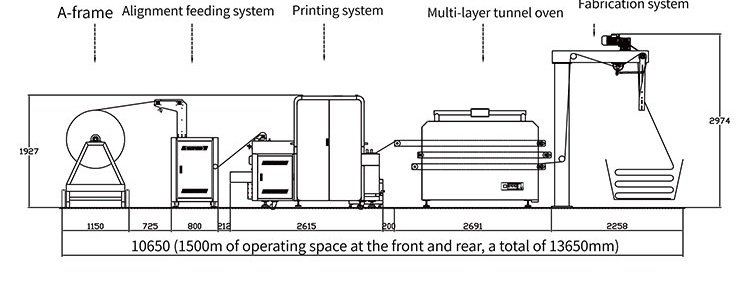

EP-I01A Belt-Guided Japan Kyocera Industrial Printhead Roll Textile Digital Fabric Printer Cooperated Machine—-Tunnel Dryer:

Belt Industrial Printer FAQ

What is the delivery time?

We typically arrange shipment within 7-25 working days after receiving full payment or a deposit. Custom orders may require additional time.

How can I get a quote for the machine?

You can visit our official website, select the product you’re interested in, and provide your email address, phone number, and product specifications. We will respond within 0-12 hours. Alternatively, you can message us on WhatsApp for immediate assistance.

What is your quality control system like? What tests are conducted before each machine is shipped?

(1) Multi-material test printing: We use various materials for practical test printing to comprehensively evaluate the printer’s performance and output quality, ensuring it meets diverse production needs.

(2) Comprehensive functional checks: Each printer undergoes detailed functional testing before shipment to ensure its printing quality and overall performance meet standards.

(3) Quality assurance review: Experienced technicians conduct final inspections to confirm compliance with strict quality standards. Any potential issues are identified and resolved to ensure flawless equipment.

(4) Careful packaging and labelling: Each printer is meticulously packaged to prevent damage during transit. Clear labels are attached for easy identification and setup. Through these rigorous quality control measures, we guarantee 100% pre-shipment testing, ensuring every UV DTF printer you receive is in perfect condition.

How can I place an order? What payment methods do you accept?

(1) After confirming the order details with our sales team, we will send you a proforma invoice. Once payment is received, we will arrange production and discuss shipping options (sea, air, or rail) based on your needs.

(2) Payment methods: T/T, Letter of Credit, PayPal, Western Union.