EP-HP06 800mm Diameter Roll-to-Roll Heat Press Machine

Roll-to-Roll Heat Press Machine Product Features:

1. Automatic correction function of felt.

2. Digital display time off, abnormal stop sound and light alarm.

3. Frequency converter failure, automatic stop heating function.

4. Can roll-to-roll, sheet-to-sheet, sheet-to-roll printing, a multi-purpose machine.

5. Speed regulating motor to drive the winding shaft winding, simple and quick operation to improve production efficiency.

Technical Data

Additional information

Product Description

Everpro Print – China’s Leading Roll-to-Roll Heat Press Manufacturer & Global Supply Partner

Industrial Continuous Thermal Transfer Solutions

✔ High-Speed Production | 1-1200m/h linear operation

✔ Precision Heat Control | Multi-zone ±0.3°C accuracy

✔ Wide Compatibility | Handles fabrics/films max can be 2.6 wide

Manufacturing Advantages

✓ Direct Factory Pricing | 35-85% below European equivalents

✓ Full Customization | Adjustable width/tension/temperature

✓ Flexible Ordering | 1-unit prototypes to bulk orders

Complete Production Support

• Turnkey Installation | Remote guidance + optional on-site training

• Authentic Components | Heating belts, rollers, sensors

• Dedicated Support | Multilingual technical team

EP-HP06 800mm Diameter Roll-to-Roll Heat Press Machine

EP-HP06 800mm Diameter Roll-to-Roll Heat Press Machine:

| Items | Roller Heat Press Machine(1) | ||||

| Model | EP-HP01 | EP-HP02 | EP-HP03 | EP-HP04 | EP-HP05 |

| Type | Multi-function | Multi-function | Multi-function | Multi-function | Roll-to-Roll |

| Drum Diameter(mm) |

200 | 270 | 420 | 600 | 600 |

| Power | 9kw | 16kw | 23kw | 50/75/90kw | 50/70/90kw |

| Voltage | 220V/50Hz (single phase) |

380V/50HZ (3phase 4wire) |

|||

| Heating Method |

Oil-based Heating Pipe | ||||

| Max Transfer Width(mm) |

1700 | 1700/1900mm | 1700/1900mm | 1700/1900/2600/3200 | 1900/2600/3200 |

| Max working speed (m/h) |

0-30 | 0-100 | 0-180 | 0-230 | 0-230 |

| Items | Roller Heat Press Machine(2) | ||||

| Model | EP-HP06 | EP-HP07 | EP-HP08 | EP-HP09 | EP-HP10 |

| Type | Roll-to-Roll | Multi-function | Multi-function | Roll-to-Roll | |

| Drum Diameter(mm) |

800 | 800 | 1000 | 1000 | 1000/1200/1500 |

| Power | 65/95/120kw | 75/100/120kw | 85kw | 85/120/150kw | 110/160/190kw |

| Voltage | 380V/50HZ (3phase 4wire) |

||||

| Heating Method |

Oil-based Heating Pipe | ||||

| Max Transfer Width(mm) |

1900/2600/3200 | 1700/1900/2600/3200 | 1900 | 1900/2600/3200 | 1900/2600/3200 |

| Max working speed (m/h) |

0-700 | 0-600 | 0-1000 | 0-1200 | 0-1200 |

EP-HP06 800mm Diameter Roll-to-Roll Heat Press Machine Parts Details:

|  |  |

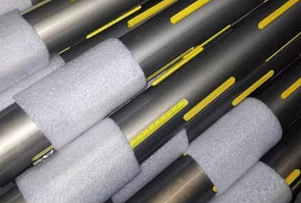

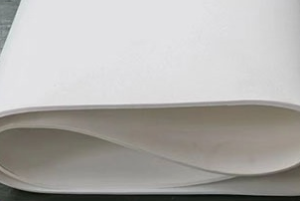

| 75% of the area was covered with felt | The standard aluminum airshaft is lightweight, durable, and designed for user-friendly operation. | The innovative design of the heating roller ensures a uniform temperature distribution, with a maximum deviation of ±1.5℃ between the left, middle, and right sections. |

|  |  |

| The transparent dust cover allows for easy monitoring of the slip ring's operational status, ensuring optimal performance. | Equipped with an automatic deviation correction system, the felt mechanism maintains optimal positioning during operation. | With efficient rewinding and unwinding capabilities for external pad paper, the system minimizes downtime by eliminating the need for frequent paper roll changes. |

|  |  |

| The system features a digital display for timed shutdown, abnormal shutdown detection, and sound and light alarms for over-temperature conditions. | The standard high-grade felt is designed for durability and exceptional performance, ensuring a long service life and optimal results. | Control Center |

Roll-to-Roll Heat Press Machine Application:

The roller heat press machine is a highly efficient and versatile piece of equipment widely used across multiple industries, primarily for heat transfer, sublimation printing, and other heat pressing processes. Thanks to its efficiency, flexibility, and multifunctional capabilities, the roller heat press machine is extensively applied in industries such as apparel printing, textiles printing, footwear printing, advertising printing, packaging printing, cultural and creative products printing, industrial manufacturing, automotive decoration, printing and education. It not only meets the demands of both personalized customization and mass production but also provides efficient and high-quality printing solutions for various sectors, making it an essential tool in modern heat transfer and heat pressing processes.

Roll-to-Roll Heat Press Machine Working Flow:

Roll-to-Roll Heat Press Machine Cooperated Machine–Paper Sublimation Printer:

FAQ

Do you accept the OEM design?

yes, just send us your requirement or the designs

What kind of technical support do you provide? How do you resolve issues during use?

Pre-sales consultation: Our sales team offers tailored recommendations based on your needs to ensure the UV DTF printer aligns with your business goals.

(2) Training and tutorials: We provide detailed operation training and tutorials to help you maximize the machine’s capabilities and improve productivity.

(3) Fault resolution: If an issue arises, our technicians will analyze the problem based on your description, photos, or videos and provide a suitable solution promptly.

How can I get a quote for the machine?

You can visit our official website, select the product you’re interested in, and provide your email address, phone number, and product specifications. We will respond within 0-12 hours. Alternatively, you can message us on WhatsApp for immediate assistance

What is your quality control system like? What tests are conducted before each machine is shipped?

(1) Multi-material test printing: We use various materials for practical test printing to comprehensively evaluate the printer’s performance and output quality, ensuring it meets diverse production needs.

(2) Comprehensive functional checks: Each printer undergoes detailed functional testing before shipment to ensure its printing quality and overall performance meet standards.

(3) Quality assurance review: Experienced technicians conduct final inspections to confirm compliance with strict quality standards. Any potential issues are identified and resolved to ensure flawless equipment.

(4) Careful packaging and labelling: Each printer is meticulously packaged to prevent damage during transit. Clear labels are attached for easy identification and setup. Through these rigorous quality control measures