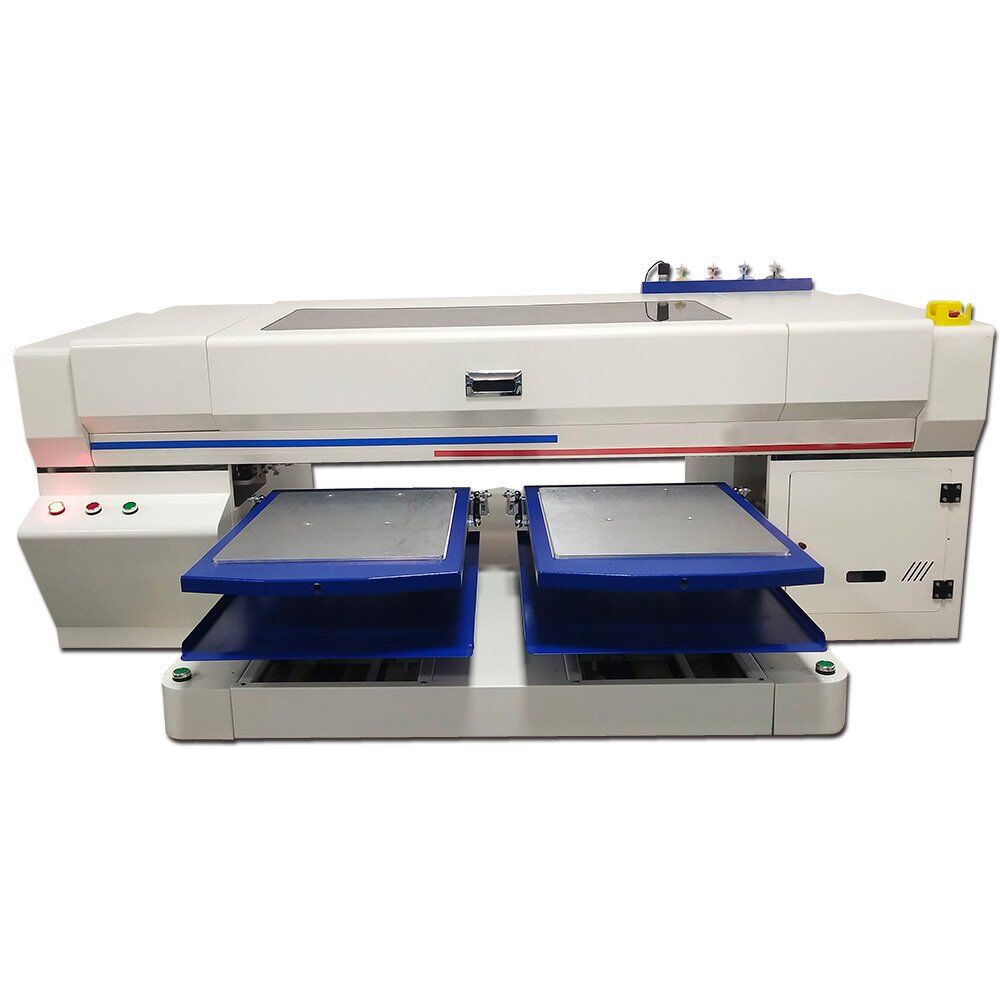

DTG-EP02 Double-Stations White Ink DTG Printing Machine

White Ink DTG Printing Machine Top Feature:

- Alternating printing of double-station tasks, and intelligent switching of stations.

- Automatic cleaning at standby time to reduce the risk of white ink plugs.

- Ergonomic garment table design, no neckline.

- Automatically generate white ink channel, Simpler operation.

- Equipped with the humidification function at the bottom of the nozzle and double flash jet tank, continuous printing and ink.

Technical Data

Additional information

| Print Head | 3*EPSON I3200-A1/4*EPSON-A1 I3200 |

|---|---|

| Printing Speed | A3 2-3.5 min/pcs |

| Print Size | 35*45cm/45*55cm |

| Ink | CMYK+W CMYK+ORGB+W |

| RIP Software | XBYX |

Product Description

Everpro Print – China’s Leading White Ink DTG Printer Manufacturer & Wholesale Supplier

Specialized White Ink Technology

✔ Vibrant Underbase Printing – Superior opacity on dark fabrics

✔ Dual-White Ink System – Double-layer application capability

✔ All-Fabric Compatibility – Cotton/polyester/linen blends

Competitive Manufacturing Advantages

✓ Direct Factory Pricing – 20-50% below market rates

✓ Full Customization – Machine dimensions/ink configuration

✓ Single Unit Orders – Ideal for small businesses

Complete Production Package

• Professional Setup – Remote/onsite installation support

• Genuine Supplies – White ink, pretreatment, maintenance kits

• Technical Hotline – 24/7 multilingual assistance

Double-Stations White Ink DTG Printing Machine

DTG-EP02 Double-Stations White Ink DTG Printing Machine Data:

| Device Type | DTG-EP02 Double-Stations White Ink DTG Printing Machine | Printhead Head | i3200-A1 |

| Print Head Quantity | 3、4 | Working Environment | Temperature:20C-28C Humidity:45-65% |

| Ink | 4colors(CMYK) 8 colors(CMYKORGB) | Working Power Supply | 220V 50HZ/60Hz 8A |

| Suitable fabric | Cotton or fabric with high-cotton | Outside Dimensions | 1900*1400*880mm L*W*H |

| RiP Software | XBYX | 2100*1540*1100mm | |

| Print Speed | 6pass 2min/piece (3h) 8pass 3.5min/piece(3h) 6pass 1min/piece (4h) 8pass 2min/piece(4h) | Weight | 240kgs/280kgs |

| Printhead Maintenance | Automatic Cleaning Automatic Moisturizing Automatic ink scraping | Power | 1000w |

| Max Print Size | 35*45cm/45*55cm | Ink barrel volume | 1500ml |

| Device Features |

2. Monochrome ink cleaning. 3. The machine can be stopped at any time without ink leakage or nozzle clogging, and the nozzle can remain moist for long-term downtime. 4. Air loss protection device for the print head. 5. The main air source can be cut off during printing or standby without any impact. | ||

Double-Stations White Ink DTG Printing Machine Parts Details:

| 3/4 I3200 printheads print faster | Guide: High quality guiderail,high printing accuracy and low noise. | Double printing platform: Alternate printing, fast production |

| Cartridge: Circulatingstirring does not plug | Printheads collision avoidance:Anti-scratch and anti-collision deviceto reduce sprinkler damage. | Action buttons: lt is moreconvenient to lift the printheads |

DTG-EP02 Double-Stations White Ink DTG Printing Machine Application:

DTG (Direct-to-Garment) printing technology, with its high precision, flexibility, and eco-friendly features, is widely applied across multiple fields, making it particularly suitable for personalized customization and small-batch production. Examples include personalized pattern printing on garments such as T-shirts, hoodies, skirts, and pants; providing small-batch, multi-variety customized designs for fashion brands; printing patterns on functional apparel like sportswear and yoga wear; creating personalized designs for sneakers and casual shoes; and offering custom printing for baseball caps and bucket hats.

Double-Stations White Ink DTG Printing Machine Working Flow:

Corresponding Product Recommend-1 station DTG printer

DTG Printer FAQ

Does DTG printing require pre-treatment of the fabric?

Yes, pre-treatment is necessary, using a pre-treatment solution. The main purpose of pre-treatment is to provide better coverage. The adhesive in the pre-treatment solution helps with adhesion and ensures wash durability.

Besides the printer, are other auxiliary machines needed for DTG printing?

Yes, besides the printer, a heat press machine is required both before and after printing. Before printing, the heat press is used to flatten the shirt, improving the printing quality. After printing, heat pressing again helps to set the ink and make it more wash-resistant.

What is the warranty period for the DTG printer?

Except for the printhead, our machines come with a one-year warranty. During the warranty period, if any quality issues arise with the equipment, we will repair or replace the faulty parts free of charge. Each machine will also come with an appropriate number of consumable parts, which will be shipped together with the machine.

Important Reminder: The warranty does not cover damages caused by improper use, accidents, or unauthorized modifications.

How can I place an order? What payment methods do you accept?

(1) After confirming the order details with our sales team, we will send you a proforma invoice. Once payment is received, we will arrange production and discuss shipping options(sea, air, or rail) based on your needs.

(2) Payment methods: T/T, Letter of Credit, PayPal, Western Union.